If you go to a store that is dedicated to the sale of cargo control supplies and ask for e-track tie-down straps, the employee who works there will give you the option of either horizontal or vertical placement of the straps. In point of fact, there are two distinct varieties of e-track, and each one is designed to accommodate a different cargo control strategy. Right here you will be able to obtain the necessary assistance in making a decision between horizontal and vertical e track straps. Both functions are carried out in the same way. The only difference is in the presentation of the anchor points in relation to the overall distance of the track. This is the only difference. Having said that, the distinction is important to keep in mind for a variety of different types of loads.

Horizontal E-Track

Out of the two distinct possibilities, the horizontal e-track layout is the one that is selected for implementation the majority of the time. The term "track" comes from the fact that the track is designed to be mounted in a horizontal fashion along the interior of a dry goods or box truck, either on the walls or along the floor. This is the origin of the term "track."The top and bottom edges of the track, as well as the track's anchor points, are all intended to have a relationship that is perpendicular to one another when assembled. Horizontal e-tracks flourish in the environment of box trucks because these trucks typically transport a wide variety of loads, which do not always fill up all of the available dead space in the box. As a result, box trucks provide an ideal environment for the use of horizontal e-tracks. Horizontal tracks offer the greatest possible number of anchor points, which paves the way for an infinite number of distinct cargo control strategies to be put into action.

For example, a truck driver may use load bars that extend across the entirety of the width of the box in order to stop the cargo from moving from the front to the back of the box or vice versa. As long as a load is secure from side to side, it is possible that load bars are the only thing that is required to keep things in place. The fact that load bars can be assembled and disassembled in a relatively short amount of time is the primary advantage that they provide. They come equipped with specialized ends that are made to easily slide into anchor points and then snap firmly into position once they are in place.

Loads that need a little more control than the average tie down can be secured with bungee cords, ropes, or mesh straps instead of the typical tie downs. The driver has the option of either making use of the anchor points that have already been installed or of attaching any additional D-rings, hooks, or other anchor points that are required. It doesn't take much to outfit a trailer or box truck with the appropriate number of e-tracks in just a few minutes. This is because horizontal tracks can be quickly and easily secured with screws. As little as five minutes is all that is required to complete this task.

E-Track that travels in the vertical direction

The reason why E-tracks are referred to as vertical is because the orientation in which they are supposed to be installed is vertical. Because the anchor points are designed to be parallel to the inside and outside edges of the track, it is possible to adjust the height of the load bars, straps, and bungee cords that are used with the track. When the height of the loads being hauled varies from journey to journey, the most efficient system to use is a vertical one to keep track of everything.

Some flatbed truckers have devised creative uses for vertical e-track, such as attaching e straps directly to the bed of the trailer in order to make use of it. This is just one example of the many uses that have been developed. This gives drivers a wide variety of options for securing their cargo against movement by providing anchor points that run parallel to the outside edges of the trailer. However, e-track shouldn't be relied on as the only method of anchor points for flatbed loads; this is something that should be avoided at all costs. They should only provide supplementary anchor points that can be used for additional anchoring or to secure tarp overloads that have already been solidly anchored. This is the only purpose for which they should be used.

We Are Able To Access The E-Track System

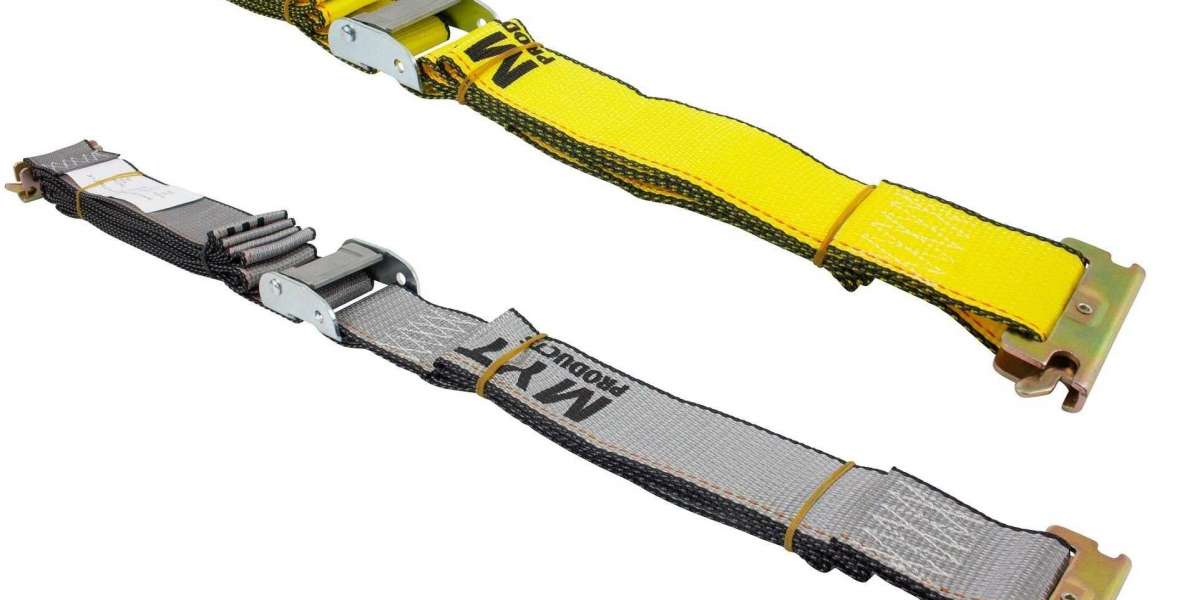

When searching for an e-track system, you should look for a galvanized product that is made of high-grade steel. This is the type of product you should look for. Both horizontal and vertical e-track can be purchased from Mytee Products. Both types of e-track are made from galvanized steel with a gauge of 12, and they feature anchor points every 2 inches. We provide them in lengths of 5 feet so that they can be easily configured into a variety of different arrangements.

When it comes to any of your trucking supplies, quality should be your top priority. This holds true regardless of the supply. You will be able to save a significant amount of money in the long run if you spend a little bit more money now on a product that is of a higher quality. This is because you won't have to replace the product as frequently. We would appreciate it if you would take a look at our e-track as well as the other products that are connected to it, such as load bars, ratchet straps, cam straps, and cam buckles. We have everything you need to ensure the safety and security of your cargo, including everything that you may require.

A Step-by-Step Guide to Securing Your Cargo with an E-Track System, which is Part of an Enclosed Trailer Tie-Down System

The majority of our conversation in this piece about the management of cargo will focus on flatbed trailers because of their widespread use. On the other hand, we must be careful not to discount the significance of dry goods trailers. Even though enclosed trailers have four walls and a roof, which in some respects makes them more suitable for cargo control, cargo still needs to be kept in place while it is being transported in order to prevent damage from occurring. The E-track tie-down system is a kind of system that is also known as an enclosed trailer tie-down system from time to time.

When you have walls to work with, it is unquestionably a little bit easier to control the cargo that is being transported. In point of fact, racecar drivers can use the E-track system to turn the walls to their own advantage, which is a significant advantage. E-track is typically already installed in the vast majority of today's dry goods cargo vans and enclosed trailers, relieving drivers of the responsibility of putting it in themselves. In order for the system to be referred to as an E-track system, the trailer needs to have at least one E-track installed on each side of the vehicle. On occasion, there are multiple tracks available for listening. The name "tracks" refers to the pattern that the receiving holes have, which is how the tracks got their name. These holes are intended to provide space for a locking mechanism that, when seen from the side, resembles the letter 'e.'

Search

Popular Posts

-

Cнять квартиру в Минске на сутки

By worksale

Cнять квартиру в Минске на сутки

By worksale -

Купить диплом с бесплатной доставкой: Успешное будущее на расстоянии одного заказа

By worksale

Купить диплом с бесплатной доставкой: Успешное будущее на расстоянии одного заказа

By worksale -

Our organization provides call girls in Aerocity and call girl in chanakyapuri as well.

By Delhi Night

Our organization provides call girls in Aerocity and call girl in chanakyapuri as well.

By Delhi Night -

Закажите необходимый диплом или аттестат на оригинальном бланке

By worksale

Закажите необходимый диплом или аттестат на оригинальном бланке

By worksale -

Продвигайтесь в карьере с помощью приобретенного диплома

By worksale

Продвигайтесь в карьере с помощью приобретенного диплома

By worksale