The extraction of natural gas is a process that is challenging and complex, and it requires the use of modern technology in order to be successful. Natural gas is an essential source of energy, and its production involves these steps. The natural gas industry must work to improve the extraction processes that are currently in place in order to cut expenses and boost productivity in order to meet the rising demand of consumers. The utilization of gas production simulators has developed into a tool that is becoming an increasingly important component of the natural gas industry. With the help of these simulators, engineers are able to simulate and optimize the extraction process, which enables a reduction in costs while simultaneously resulting in an increase in production rates.

What exactly does ESIM-FGR3 gas production Simulator mean when someone refers to something as a Gas Production Simulator?

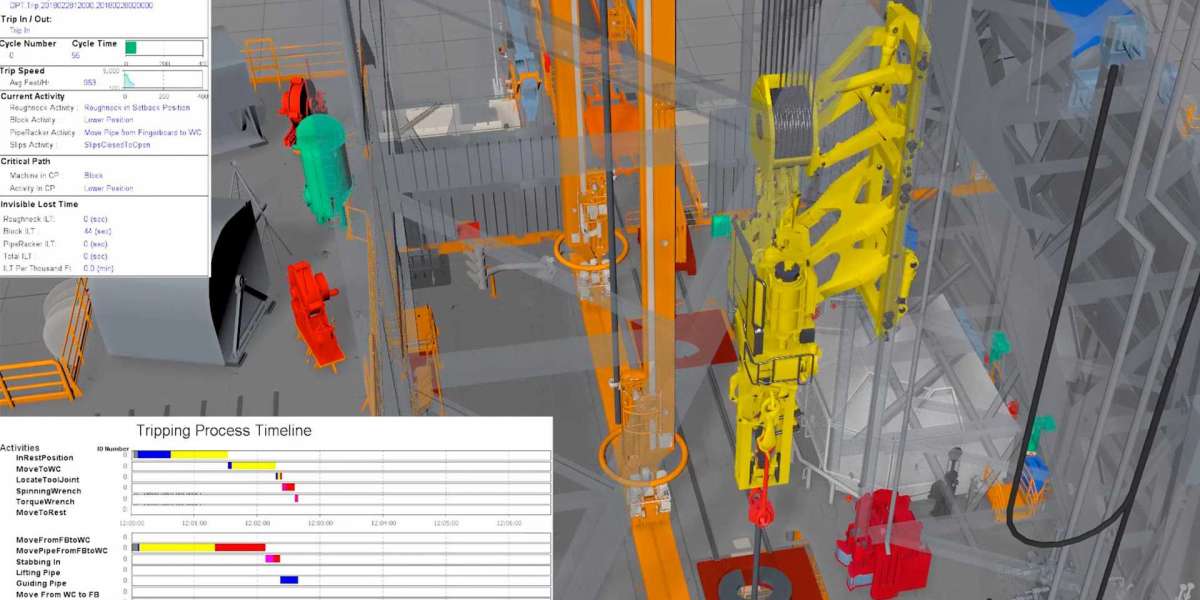

Using a piece of software called a gas production simulator, engineers are able to model the behavior of gas that is contained within a reservoir. This modeling is possible thanks to the software. The manufacturing process is also modeled in this program's simulation. The behavior of gas in a variety of environments is modeled mathematically by the simulator, which allows for simulation of that behavior. Engineers are given new insights as a result of this, including the anticipated production rate as well as potential optimizations that can be made. Gas production simulators have the capability of simulating a wide variety of production techniques, including gas lift, gas injection, and other methods that are used to improve recovery rates.

The following characteristics can be found in gas production simulators:

The following is a list of some of the features that gas production simulators offer in order to facilitate the optimization of the extraction process:

Modeling of a Water Supply ReservoirThe simulator is able to reproduce the behavior of gas in a reservoir even when subjected to a wide range of different conditions. This gives engineers a better idea of the expected production rate as well as potential areas for improvement.

Multi-Phase Flow Simulation: The simulator is able to simulate the behavior of gas, oil, and water in the subsurface. Specifically, the simulator can simulate multi-phase flow. As a consequence of this, it is able to provide engineers with insights into the impact that various methods of production have on the extraction process.

Simulation of Gas Injection One common method that is used to improve gas recovery rates is gas injection, which can be simulated here. The simulator is able to simulate gas injection and determine which methods are the most effective for injecting gas into a specific reservoir. This is done by determining which techniques produce the most accurate simulation results.

Simulation of Gas Lift: Gas lift is another technique that can be used to improve gas recovery rates. Gas lift can be modeled using simulation software. The simulator is able to perform a simulation of gas lift and determine which methods are the most efficient for lifting gas from a specific reservoir. This capability is known as "gas lift simulation."

Examples of Some of the Many Uses That Gas Production Simulators Can Have

Gas production simulators are put to use in the natural gas industry for a wide variety of reasons, including the following:Using the simulator, one can plan the development of gas fields and determine the most effective methods of extraction based on the characteristics of the reservoir

This can be done by using the simulator

Optimization of Production: The simulator can be used to simulate various production scenarios in order to determine which production methods are the most productive while also being the most cost-effective

This can be done in order to optimize production

Reservoir Management: The simulator has applications in reservoir management, where it can be used to monitor and improve the efficacy of recovery rates and reservoir performance

Specifically, the simulator can be used to monitor and improve reservoir performance

Analyzing Risk: The simulator can be used to evaluate the potential risks associated with various production scenarios and identify potential strategies for mitigating those risks

In addition, the simulator can be used to identify potential strategies for improving the quality of the product

In addition to the features that are shared by all gas production simulators, it's possible that some gas production simulators have their own unique set of additional features. A sophisticated graphical interface and various tools for calibrating models are examples of these additional features. Engineers can benefit from having access to an intuitive and user-friendly platform thanks to these additional features, which can be used for simulating and improving the extraction process. This can be done for the purpose of improving the extraction process.

In addition, gas production simulators are used not only in the natural gas industry but also in other industries that involve gas production, such as the liquefied natural gas (LNG) industry. This is because gas production simulators are able to replicate the complex processes involved in producing gas. This is due to the fact that the requirements for the natural gas industry and the requirements for other industries that produce gas are very similar. Compressing natural gas and then cooling it to a temperature of -120 degrees Celsius results in the production of a product that is known as liquefied natural gas, or LNG for short. The extraction process that is involved in the production of LNG is complicated and challenging, in a manner that is comparable to that of the industry that deals with natural gas. The utilization of gas production simulators has become an absolute requirement in the LNG industry as a means of meeting the challenge of achieving the highest possible level of productivity throughout the LNG extraction process.

In addition, the advancement of cutting-edge computing technologies has resulted in a significant rise in the use of gas production simulation software, which has led to an increase in the overall production of gas. When using high-performance computing systems, engineers are able to simulate complex reservoirs and production scenarios at a faster rate. This is possible because the systems are more powerful. Because of this, they are now in a position to optimize the extraction process in a way that will result in greater productivity.

In conclusion, gas production simulators are essential pieces of equipment in the natural gas and LNG industries for optimizing the procedures involved in the extraction of gas. These simulators can be found in both land-based and offshore gas production facilities. Engineers are able to gain insights into both the anticipated production rate as well as potential optimizations thanks to the capability of these simulators to simulate and optimize a variety of production scenarios. When it comes to the process of planning the development of a field, optimizing production, managing reservoirs, and performing risk assessments, these tools are an absolute necessity. As a result of developments in computing technology, the utilization of gas production simulators has become significantly more potent and effective. Because of this, the gas industry is now operating in a way that is both more productive and more environmentally friendly.