Introduction

In the realm of manufacturing and metalworking, coated abrasives are unsung heroes, silently contributing to the precision and efficiency of countless processes. Coated abrasives, consisting of abrasive grains bonded to a flexible backing, find applications in tasks ranging from sanding and grinding to polishing and finishing. This article delves into the world of coated abrasives companies, exploring their significance, product offerings, and the evolving landscape of this indispensable industry.

Understanding Coated Abrasives: The Art of Precision

Coated abrasives are a class of abrasive products where abrasive grains are evenly distributed on a backing material such as paper, cloth, or polyester. The choice of abrasive grains and backing materials is tailored to the specific application, ensuring optimal performance in tasks that demand precision and control.

Applications Across Industries

Metalworking and Manufacturing:

Coated abrasives are the go-to tools in metalworking and manufacturing. From shaping and deburring to finishing and polishing, coated abrasives play a crucial role in refining surfaces and achieving the desired level of smoothness. Whether it's preparing a surface for painting or removing imperfections in metal components, coated abrasives are indispensable in the production process.

Woodworking:

In the woodworking industry, coated abrasives find extensive use in sanding and finishing applications. Woodworkers rely on these abrasives to achieve smooth surfaces on wooden furniture, flooring, and other products. The flexibility of coated abrasives allows for precision in intricate woodworking tasks, contributing to the overall quality of the finished product.

Automotive Industry:

Coated abrasives are integral to the automotive industry, playing a vital role in the manufacturing and repair of vehicles. Whether it's sanding body panels, smoothing welds, or polishing surfaces, coated abrasives contribute to the aesthetic appeal and functionality of automotive components.

Construction and DIY Projects:

Coated abrasives also find a place in construction and do-it-yourself (DIY) projects. From sanding drywall to preparing surfaces for painting, these abrasives make tasks more manageable and contribute to achieving professional-quality results.

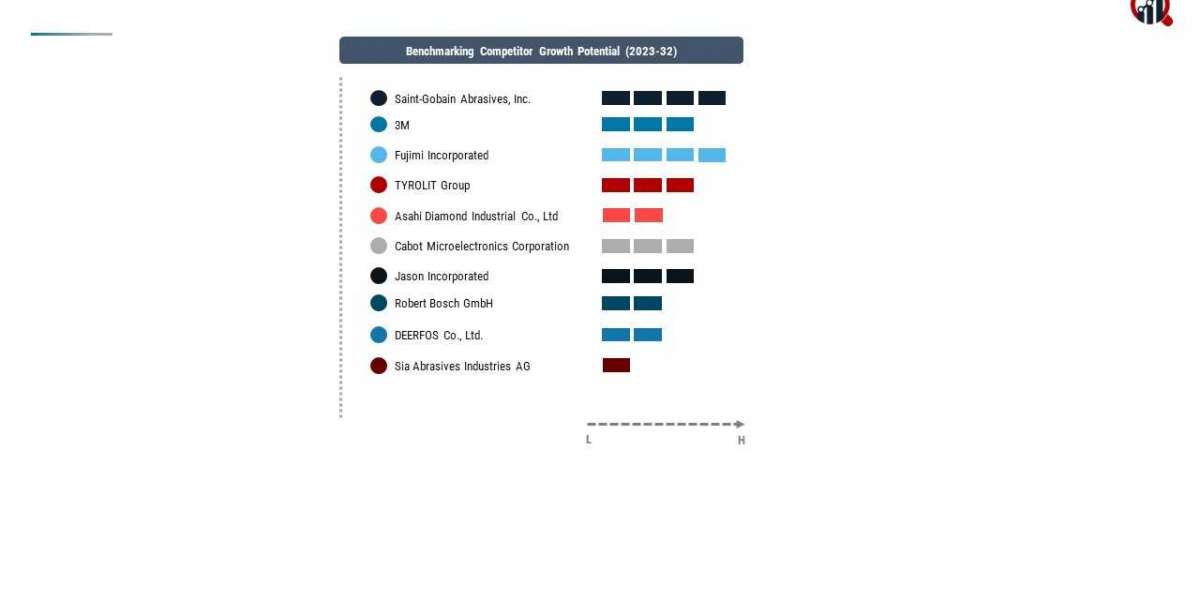

Key Players and Market Dynamics

Several companies globally specialize in the production of coated abrasives, catering to the diverse needs of industries. 3M, Saint-Gobain Abrasives, and Mirka are among the key players in this competitive market. These companies invest in research and development to introduce innovative products, improve manufacturing processes, and meet the evolving demands of their customers.

The coated abrasives market is influenced by factors such as advancements in technology, the demand for high-quality finishes, and the expansion of end-use industries. As industries continue to prioritize efficiency and precision, the demand for coated abrasives remains robust.

Challenges and Innovations: Navigating the Abrasive Landscape

The coated abrasives industry faces challenges related to environmental sustainability, as traditional abrasive materials may raise concerns about their ecological impact. In response, companies are increasingly exploring eco-friendly alternatives and adopting sustainable practices in their manufacturing processes. This shift aligns with the broader global trend of embracing environmentally responsible business practices.

Innovation is also a driving force in the coated abrasives industry. Companies are introducing new abrasive materials, developing advanced bonding technologies, and creating abrasives with longer lifespans to enhance overall efficiency and cost-effectiveness.

In conclusion, coated abrasives companies are instrumental in shaping the landscape of various industries by providing essential tools for precision and efficiency. As technology advances and industries evolve, these companies will continue to play a vital role in meeting the ever-growing demands for quality and performance in manufacturing and finishing processes. With a commitment to innovation and sustainability, the coated abrasives industry is poised for a future where precision meets environmental responsibility.

Read more about the company page coated abrasives key companies